Real-Time Production Control & Traceability

Digital Transformation of Manufacturing Operations

Advanced MES system that replaced manual tracking with real-time, serial-number-based control over every stage of transformer production.

Reduction in Manual Errors

Real-Time Visibility

Faster Production Tracking

Reduction in Manual Errors

Real-Time Visibility

Faster Production Tracking

Manual Processes, Zero Visibility

The main challenge for Axis Technologies was fully digitizing SEA's production without using an existing software model. SEA was using physical documents and disjointed Excel sheets to manually manage all production paperwork, tracking, and reporting.

- •Manual paper-based tracking causing delays and errors

- •No existing MES system to reference or build upon

- •Complex transformer production requiring precise documentation

Complete Digital Transformation

Axis Technologies effectively integrated all required customizations and standard MES features into a feature-rich system that digitalized SEA's manual processes, providing real-time visibility and control.

- •Digital workflow replication with intuitive operator controls

- •Serial number traceability for complete production history

- •Seamless ERP integration for synchronized operations

Digital Workflow Replication

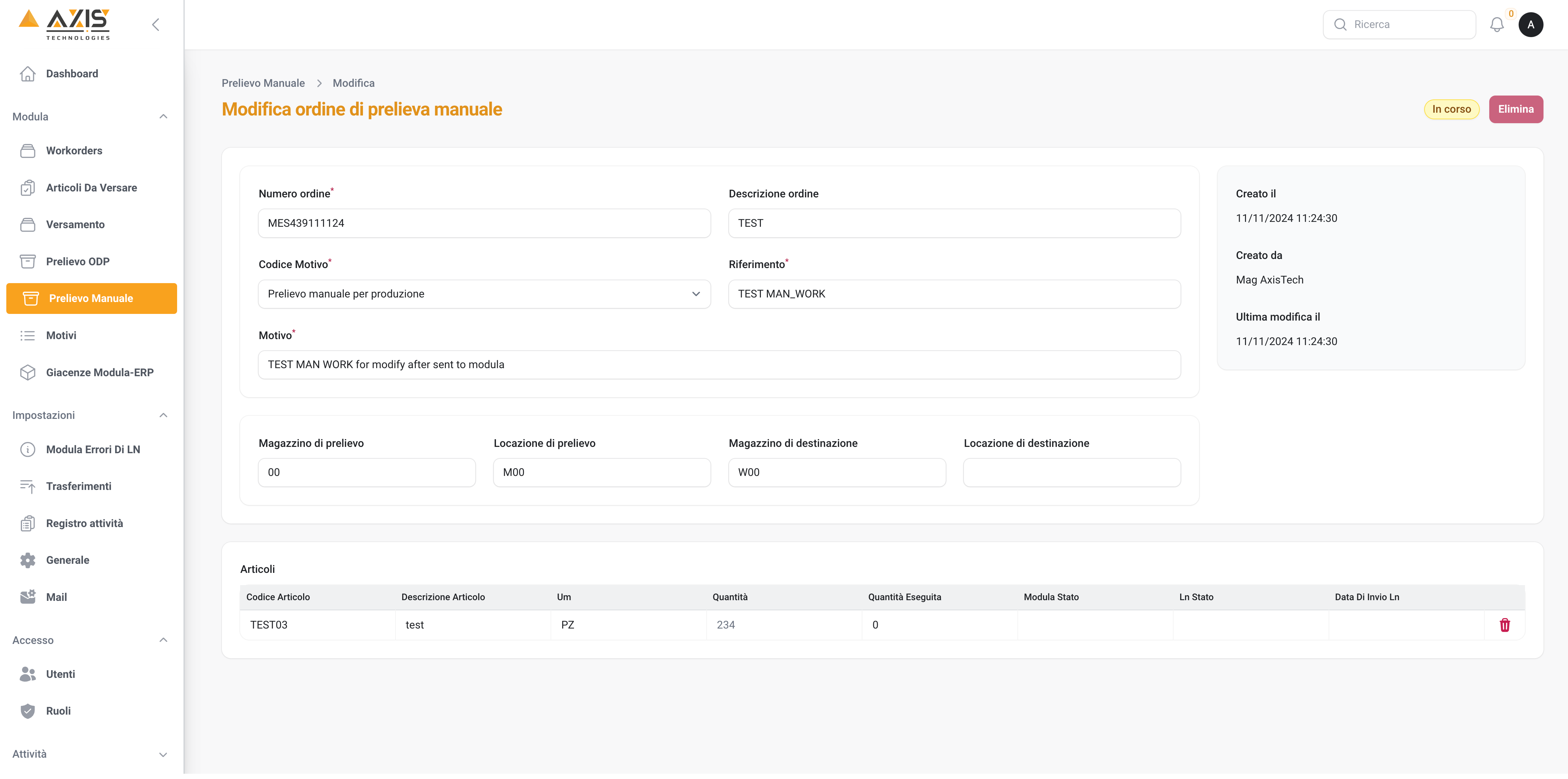

Using straightforward Start, Pause, Continue, and Complete buttons, the fundamental Work Order Operations were created to accurately replicate the operator's manual actions. This allowed for the automatic logging of the real End Date and the collection of precise real production timings.

Unmatched Traceability

Users may quickly obtain the complete history of any transformer serial number, including all operations, materials, replacement parts, and tools used, thanks to the Serial Card feature, which offers a personalized, one-click traceability solution.

Comprehensive Scheduling and Resource Management

With the help of comprehensive configuration modules for Operators, Work Centers, Tasks, Tools, and Working Hours, the system provides robust scheduling through the Calendar Machine, which determines total machine hours based on quantity, hours, and tolerance, as well as specialized Machine Management and Group Calendar views.

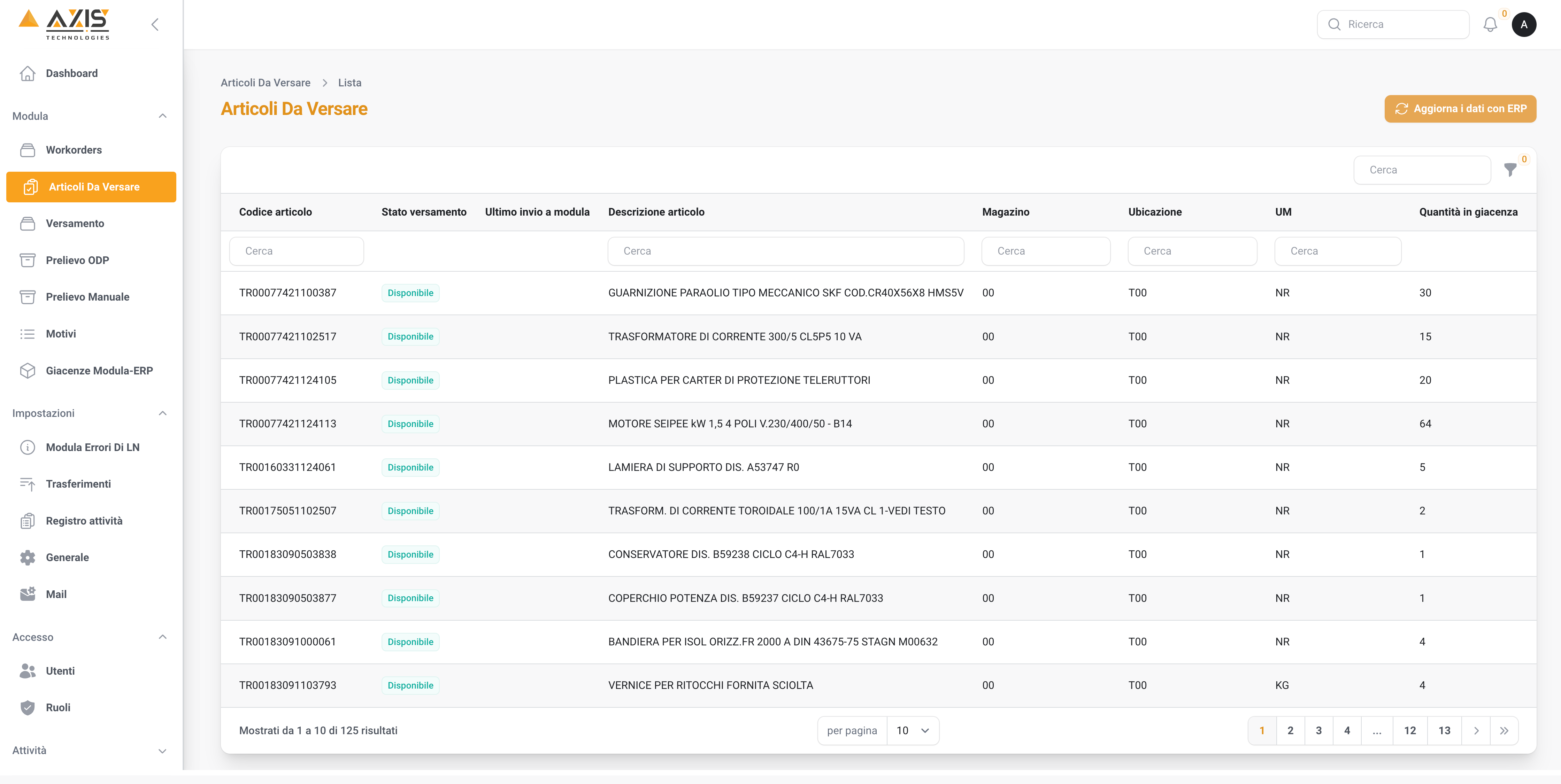

Seamless Integration

The solution created a single, transparent source of truth for all production data by establishing dependable connection with the ERP, handling Work Order Attachments, and guaranteeing that the state of operations and required documents (Documents LN) are synchronized automatically.

With the help of this solution, SEA was transformed from a manually tracked, error-prone environment to a digital production system that is effective, responsible, real-time, and prepared for future growth.

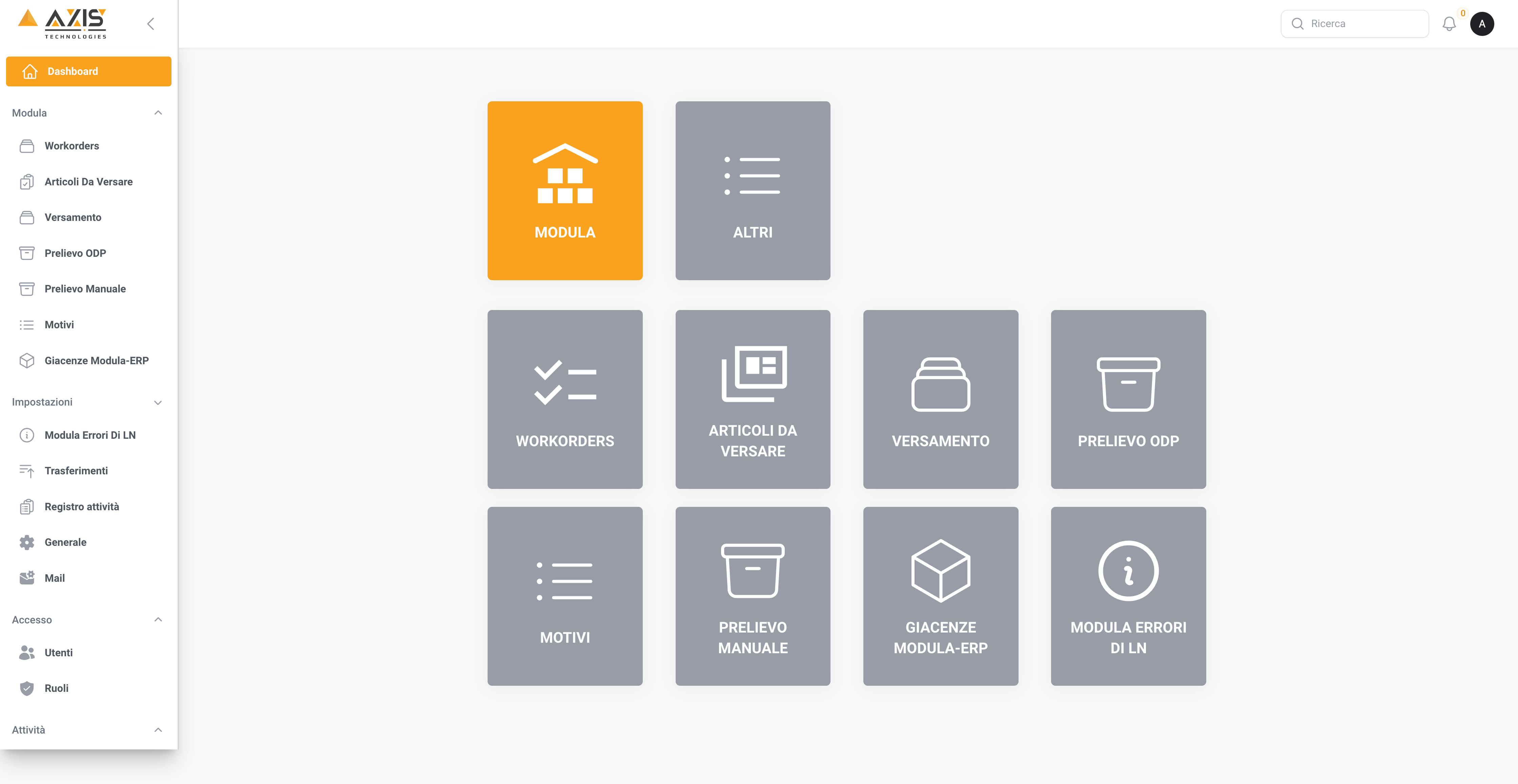

Product Features.

Designed to streamline operations and deliver measurable results across your entire organization.

Work Order Management

Complete tracking from dispatch to completion with Start, Pause, Continue, and Complete controls.

Serial Card Traceability

One-click access to complete history of any transformer including all operations, materials, and tools used.

Machine Scheduling

Calendar-based scheduling with automated calculation of production hours based on quantity and tolerance.

ERP Integration

Seamless data synchronization with ERP system for work orders, status updates, and documents.

Resource Management

Comprehensive configuration for operators, work centers, tasks, tools, and working hours.

Real-Time Monitoring

Live tracking of all production activities with automatic logging of timings and status changes.